Support

Quality control system

To Huiyun Technology, quality is our highest priority, although the price is the stepping stone to our cooperation.

We know you need quality parts quickly at a competitive price. And, that’s exactly what we do.

Today’s dynamic environment demands that we provide high quality products. Price points must be in line and products must be unique. We delivers parts to you on quality, quantity, and price.

Our quality management system has been developed over the course of a decade. We strive for a zero defects culture across all divisions of our organization. All lines undergo rigorous quality control at several key points in the production process.

Some of the certifications typically held by our company are listed below:

ISO 13485 |

|

|

|

ISO 14001 Environmental |

|

|

|

Supplier management

We only source from approved suppliers, and our supplier management program verifies all purchases. To make sure all products are sourced from trusted and proven sources, we investigate and pre-qualify our suppliers. Along with tracking inventory supply or demand, order history, performance, and service fulfillment, we also keep tabs on quality history.

Appearance inspection

We will conduct appearance inspection of all warehousing goods and make detailed inspection records.

1. Manufacturer, manufacturer's part number, quantity, production date and environmental standard testing.

2. Outer packaging inspection, whether the packaging is in good condition or complete, and whether the packaging materials meet the requirements of the corresponding MSL standards.

3. Screen printing (Marking) inspection, consistency inspection, check original specifications and documentation.

4. Material appearance inspection, dust condition, whether the pin is deformed, and whether the pin has signs of oxidation.

Engineer review

All suspicious materials found in the visual inspection, or materials supplied by suppliers that are not 'first-tier suppliers' in the system, must be re-inspected by engineers.

1. Review the visual inspection process.

2. Refer to quality control database, check manufacturer's label or logo, code identification.

3. Barcode scanning detection.

4. Check with the original factory for the Lot No., production date, and the corresponding origin of the wafer or package.

5. Simple electrical performance test.

Quality test

All products that are not identified during the engineer's re-inspection process will enter the quality testing process.

1. Solderability testing.

2. Anatomical analysis.

3. Electrical performance compliance test.

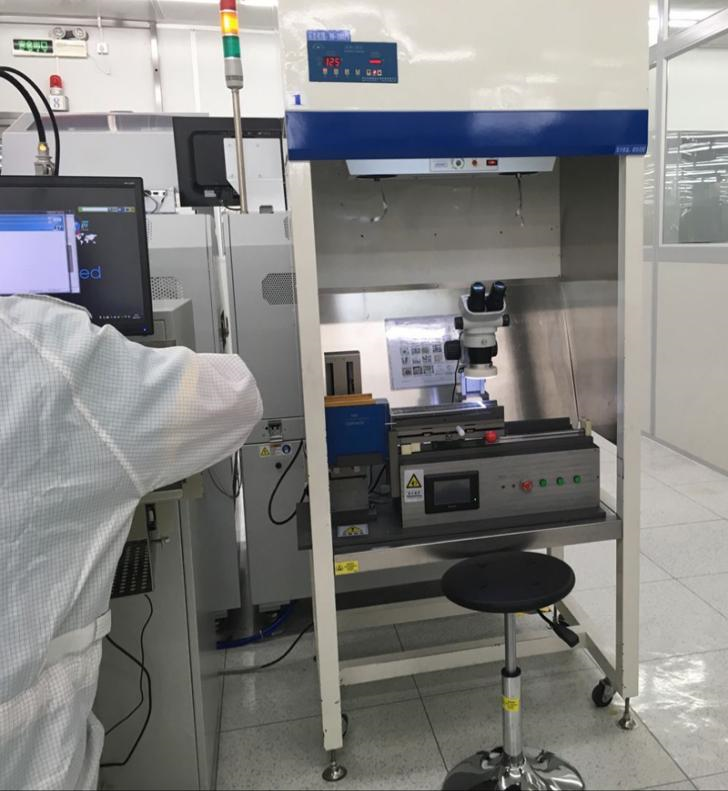

On-site test photo return

|

|

【 Go Back 】 | 【 Print 】 | 【 Close this window 】